- Register

- Log in

- Wishlist 0

- Shopping cart 0You have no items in your shopping cart.

- Check Order Status

PYI Incorporated

PSS Shaft Seals boast a durable and flexible design that allows use in marine and industrial applications. They require minimal maintenance, which helps reduce downtime on standard equipment. The units are manufactured by PYI Inc., a leading supplier of marine and industrial components. Deep Blue Yacht Supply is your trusted source for the entire line of PYI PSS packless dripless marine shaft seals. All PYI PSS marine shaft seals are offered up at the lowest price possible, and are able to be shipped to over 125 countries worldwide.

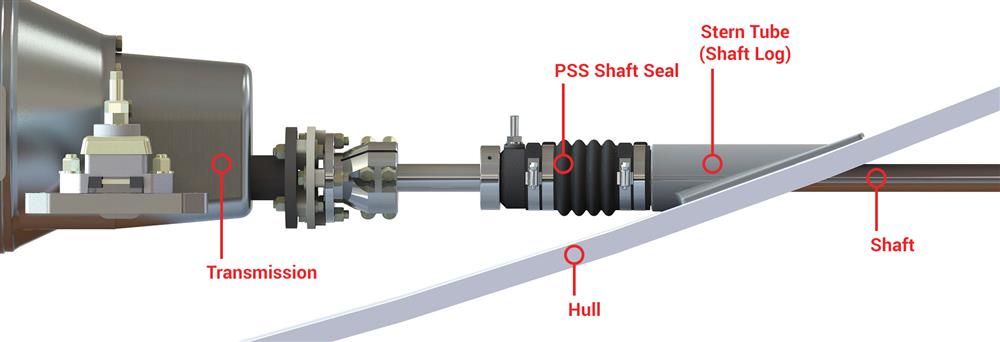

As a mechanical face seal, each unit can be customized to meet specific design or installation requirements. Many boat yards and boat builders rely on this level of flexibility to achieve water-tight installations. Engineers take advantage of the seals to eliminate constraints associated with traditional packing type glands.

Marine

It comes as no surprise that the US Coast Guard and various certification bodies approved the use of PSS Shaft Seals on marine equipment. In addition, the product is a top seller around the world in the marine mechanical seal category. It also performs well in the retrofit (aftermarket) seal segment.

Boat yards and boat builders prefer the PSS Shaft Seal by PYI Inc. because the component does not require constant adjustment. The reduction in cost is another key benefit that makes the product an attractive option. Some of the mechanical advantages of using PSS are that it helps reduce wear and tear on the propeller shaft.

Additionally, boat owners can ensure a 100 percent water-tight fit, thus eliminating the possibility of water in the bilge. The product undergoes thorough testing to ensure reliability. It is possible to retrofit the seals on shafts ranging between 3/4 and 6 inches (20 and 150 millimeters).

Industrial

The sealing surface attaches to the flat surfaces of the carbon flange and the rotor. The flange is fitted onto the bellow and secured using hose clamps. The installations are customizable, thus increasing the variety of options for users. Custom seals can be delivered within a short time frame, typically between three and four weeks.

The product's simple design ensures both durability and reliability. Engineers can expect the units to have a working life of at least 25,000 running hours. The lifespan can increase to 100,000 running hours when used under clean water conditions. The seal can handle axial movement of the shaft thanks to the proprietary float design.

While it is obviously a better decision to keep water out of your boat than let it in, the majority of engines built today use a system of dripping to allow seawater into the engine and cool the components. This seawater corrodes or contaminates many parts of the engine, meaning the choice between overheating and slow destruction of an engine presented a lose-lose scenario to boat owners. Pss dripless shaft seals remedy this problem by using a fitting to cover the passage to the interior of the engine. This brand is the most well-used in today's marine market. Many of the best boat construction companies and shipping yards utilize this simple seal, and it has been certified by numerous different companies that construct nautical machinery.

Whether you own a boat, rent a boat, or plan to start a nautical hobby, you should know about what a pss dripless shaft sealer can do for a boat's engine. A seal can take out the process of repair, adjustment, and price that comes into packing type gland units that allow small quantities of water to enter into the engine. The standard rate of one drip per minute may seem entirely harmless, especially since the heat of the engine keeps the moisture from accumulating, but the chemicals and saline within the water do far more to harm an engine than the water itself. Using pss dripless shaft seal technology to eliminate this water completely -- the seal makes the unit entirely water tight -- helps to keep the propeller shaft from further wear and tear. What's more, the unit can be retrofitted in order to accommodate shafts that vary from twenty to one hundred fifty millimeters.

The seal itself sits between a steel rotor and a carbon flange. While the rotor turns, the flange does not, and a seal is needed to prevent movement from harming either part. The rotor works to exert force on the bellows and the pss dripless shaft seal compensates for the constant movement. Instead of requiring fluid to cool it, the polish of the gears keeps water from passing through and reduces the friction that causes more heat. Attaching a stainless steel collar to the shaft keeps the rotor, the shaft, and the rings itself from wear and tear during a motor's shelf life. Indeed, many owners report that this dripless seal can keep moisture out of their boat years after it has been installed.

Deep Blue Yacht Supply carries the entire line of PYI marine shaft seals, and offers some of the besting pricing in the world. If you have any questions on PYI PSS packless dripless shaft seals, reach out to the experts at Deep Blue Yacht Supply.