For more than 25 years, Tides Marine in South Florida has been addressing one of the most prevalent boating issues: leaking shaft seals. Tides Marine shaft seals are widely regarded as the industry standard, and they keep your bilge as dry as the rest of the boat while requiring little attention.

Key Features of the Tides Marine shaft Seals

• ABS and Lloyds Type Approval

• Little maintenance required

• Ability to replace the Lip Seal while in the water

• Winterization fluids will not harm the SureSeal, even if you don't do it

• It's simple to install and use.

Housing

The housing is constructed of fiber-reinforced composite materials that makes it strong, long-lasting, and compact. The Tides Marine shaft seal does not alter in size when it gets hot or wet, so it will not absorb water.

Bearing

The integral PTFE bearing extends the operating life of Tides Marine shaft seals under normal operating conditions.

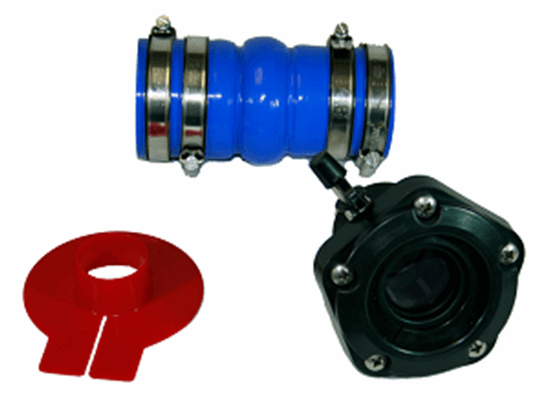

Hose

With a hose that automatically positions the Tides Marine shaft seals the correct operating distance from the stern tube, connecting the shaft seal to the vessel is now much easier. There is no need for measurement, and installation is simplified. The articulating hose lowers side loads onto the Tides Marine shaft seals and extends lip seal and bearing life when the shaft misalignment arises.

Lip Seal Replacement

Because of the straightforward access provided by the removal front cap, replacing a damaged lip seal is simple. Even while the boat is in the water, a worn lip seal may be replaced quickly, ensuring that the 100% watertight seal is restored.

Injection Fitting

The Tides Marine shaft seal water injection fitting is composed of 316 stainless steel. It is available in two different sizes: 3/8 and 1/2 inch, depending on the propeller shaft diameter. A cap for each fitting is included to prevent water from entering the vessel if the injection hose needs to be removed.

Maintenance Tips

It's critical to have your Tides Marine Shaft Seals installed and maintained correctly. Improper installation, on the other hand, might cause dangerous quantities of water to enter your boat even if you use your Tides Marine shaft seals for hundreds of hours without experiencing water into your vessel.

If you're not a professional, you'll need to find an expert when it comes to installing the seal, and familiarize yourself with basic maintenance tips is crucial.

With these tips, you can avoid marine shaft seal issues:

• Check for blockages in the pressurized water feed to the shaft seal and that the impeller is operating effectively. It is critical to maintain a constant water flow, and this should be noted in every maintenance list. If the shaft seal is not replaced, it will overheat and get damaged.

• On a yearly basis, inspect the lubrication system, hoses, clamps, and pump.• Remove the water lubrication hose from the seal shaft during maintenance. Ensure the seal's fitting is clear and that it hasn't corroded. There should be a significant flow of water from the slip into the vessel, especially when it is in the water. To prevent this inflow, use the inspection cap connected to the hose connection.

• Each engine should be idled once the boat is in the water. Check the lubrication hose for water flow at the shaft seal. At idle, the flow rate should be approximately one gallon per minute.

• Tides Marine suggests replacing the lip seals after five years.

• If you detect a slow leak that gradually increases over time, dig further and fix it right away.

• If you ever have a problem with your engine's running gear or if there are any alignment or vibration concerns, be sure to check the dripless shaft seal as well.

Reach out to the marine shaft seal experts at Deep Blue Yacht Supply to get the proper Tides Marine Shaft seal for your vessel, boat, or application.